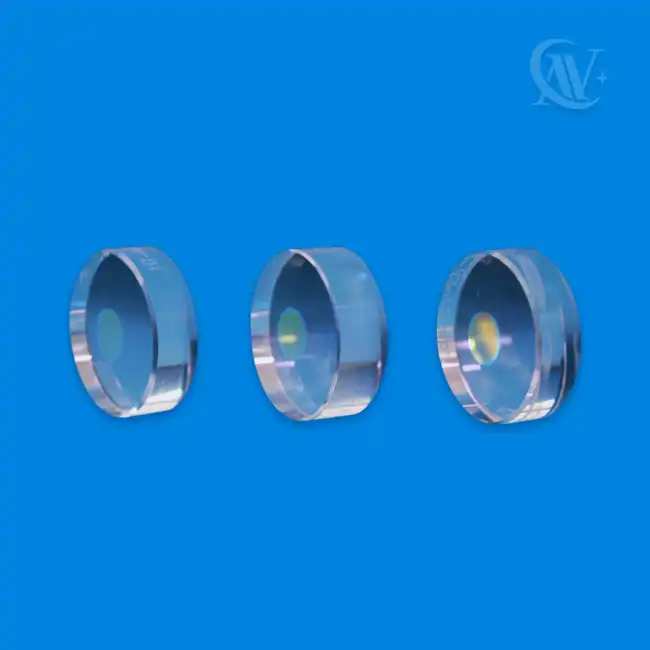

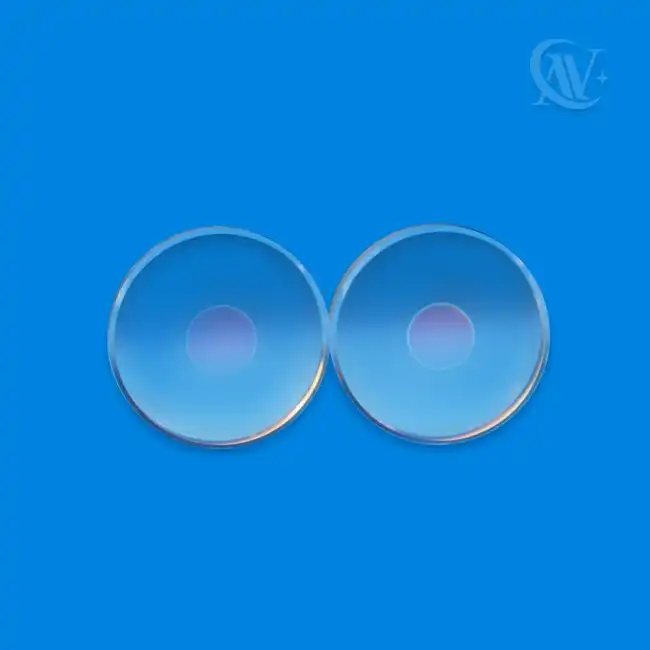

99.999% Reflective Spherical Mirror

1)D=φ12.7-φ50.8mm(tolerance±0.1),H=4-8mm D:H>4:1(tolerance±0.5) 2)D50.8-φ100mm(tolerance±0.1),H=10-25mm D:H>4:1(tolerance±0.5)

② Kickoff size:φ7.5-45

③ Coating area size: conventional size D12.7, coating area size 7.5; D25 coating area size 10, other coating area size can be customized

④ Curvature: SR=500-8000(customize),curvature accuracy±0.05%

⑤ Surface accuracy: λ/2-λ/10@632.8nm

⑥ Spherical accuracy:30"-3′

⑦ Roughness: Ra0.12nm (Zygo profilometer) test area 173*173um full frequency measurement

⑧Coating requirement: wavelength 632nm-1550nm, reflection ≥99.999%, loss 2-6ppm, transmission 3-5ppm

Back anti-reflection;

⑦ Material:ULE, fused silica,zerodur

Note: The specific indicators are not limited to the above scope, and can be customized according to user's needs.

Application:Power laser, high power laser, high precision optical inspection

- Product Description

99.999% Reflective Spherical Mirror Manufacturer and Supplier

Xi'an SNP Precision Optics CO., LTD is a leading manufacturer and supplier of 99.999% Reflective Spherical Mirrors. Our advanced manufacturing processes and stringent quality control ensure unparalleled precision and reliability in every mirror we produce. With our state-of-the-art facilities and expert team, we deliver custom solutions that meet the most demanding requirements in optics and photonics.

99.999% Reflective Spherical Mirror Introduction

Welcome to the cutting edge of optical technology with our 99.999% Reflective Spherical Mirror. These high-performance optical components are designed to meet the exacting standards of advanced research, aerospace applications, and high-power laser systems. Our mirrors boast an exceptional reflectivity of 99.999%, ensuring minimal light loss and maximum efficiency in your optical setups. Crafted from premium materials like ULE, fused silica, and Zerodur, these mirrors offer superior thermal stability and low expansion coefficients. The spherical surface is polished to perfection, achieving surface accuracies as fine as λ/10 at 632.8nm. With customizable dimensions and curvatures, our mirrors are versatile enough to integrate seamlessly into a wide range of optical systems.

Parameters

| Feature | Specification |

|---|---|

| Dimension | 1)D=φ12.7-φ50.8mm(tolerance±0.1),H=4-8mm D:H>4:1(tolerance±0.5) 2)D50.8-φ100mm(tolerance±0.1),H=10-25mm D:H>4:1(tolerance±0.5) |

| Kickoff size | φ7.5-45mm |

| Coating area | conventional size D12.7, coating area size 7.5; D25 coating area size 10, other coating area size can be customized |

| Curvature | SR=500-8000mm (customizable), ±0.05% accuracy |

| Surface accuracy | λ/2-λ/10@632.8nm |

| Spherical accuracy | 30"-3′ |

| Roughness | Ra0.12nm (Zygo profilometer) test area 173*173um full frequency measurement |

| Reflectivity | ≥99.999% (632-1550nm) |

| Loss | 2-6ppm |

| Transmission | 3-5ppm |

| Material | ULE, fused silica, Zerodur |

Applications of product

Our high-precision mirrors find applications in numerous cutting-edge fields:

- High-power laser systems

- Optical frequency combs

- Interferometry and metrology

- Aerospace and defense technologies

- Quantum optics research

- Spectroscopy and sensing

Why Choose Xi'an SNP Precision Optics for Your product?

Unmatched Quality:Employing a battery of advanced optical and mechanical tests, we measure reflectivity, surface flatness, and durability. Each mirror is tested across a wide range of environmental conditions, including temperature variations and humidity levels, to guarantee its reliability in diverse applications, from high - tech research labs to industrial production lines.

Customization: Whether you need a mirror with a unique size for a compact optical device, a specialized coating for enhanced light absorption or reflection, or a custom shape for a complex optical system, our experienced engineers collaborate closely with you.

Expert Support: From the initial stages of project planning, where they offer in - depth consultations on choosing the right mirror type and material, to post - installation troubleshooting, our experts are with you every step of the way

Advanced Manufacturing: Our manufacturing plants are equipped with high - precision CNC machines for shaping, automated polishing systems for achieving ultra - smooth surfaces, and advanced coating technologies for applying uniform and durable coatings.

Reliable Partner:We understand the importance of meeting deadlines, so we maintain an efficient production schedule and have established strong partnerships with reliable logistics providers. Moreover, we are committed to providing continuous support even after the delivery, making us a partner you can rely on for all your optical mirror needs, now and in the future.

Frequently Asked Questions

Q: Can you provide custom coating designs for specific wavelengths?

A: Absolutely! We can optimize coatings for your desired wavelength range.

Q: What is the typical lead time for custom 99.999% Reflective Spherical Mirrors?

A: Lead times vary based on specifications, but we strive for 4-6 weeks for most custom orders.

Q: Do you offer any certification or test reports with the mirrors?

A: Yes, we provide detailed test reports and certifications for all our high-precision mirrors.

Contact Us

Ready to elevate your optical systems with our 99.999% Reflective Spherical Mirror? We're here to help you find the perfect solution for your project. Reach out to our team of experts today at xachaona@163.com or visit our website for more information. Let's push the boundaries of optical technology together!

YOU MAY LIKE

VIEW MORESuper Stable Cavity Reflective Spherical Mirror

VIEW MORESuper Stable Cavity Reflective Spherical Mirror VIEW MORE99.999% ULE Reflective Mirror

VIEW MORE99.999% ULE Reflective Mirror VIEW MORED12.7 Plane Mirror

VIEW MORED12.7 Plane Mirror VIEW MORESuper-Smooth Spherical Mirror With Small Curvature

VIEW MORESuper-Smooth Spherical Mirror With Small Curvature VIEW MORESapphire Super Low Loss Spherical Mirror

VIEW MORESapphire Super Low Loss Spherical Mirror VIEW MORESingle Crystal Silicon Super Low Loss Spherical Mirror

VIEW MORESingle Crystal Silicon Super Low Loss Spherical Mirror VIEW MORECalcium Fluoride Super Low Loss Flat Mirror

VIEW MORECalcium Fluoride Super Low Loss Flat Mirror VIEW MORESingle Crystal Silicon Super Low Loss Flat Mirror

VIEW MORESingle Crystal Silicon Super Low Loss Flat Mirror

_1736302755188.webp)